-

Yuyao, Ningbo City, China

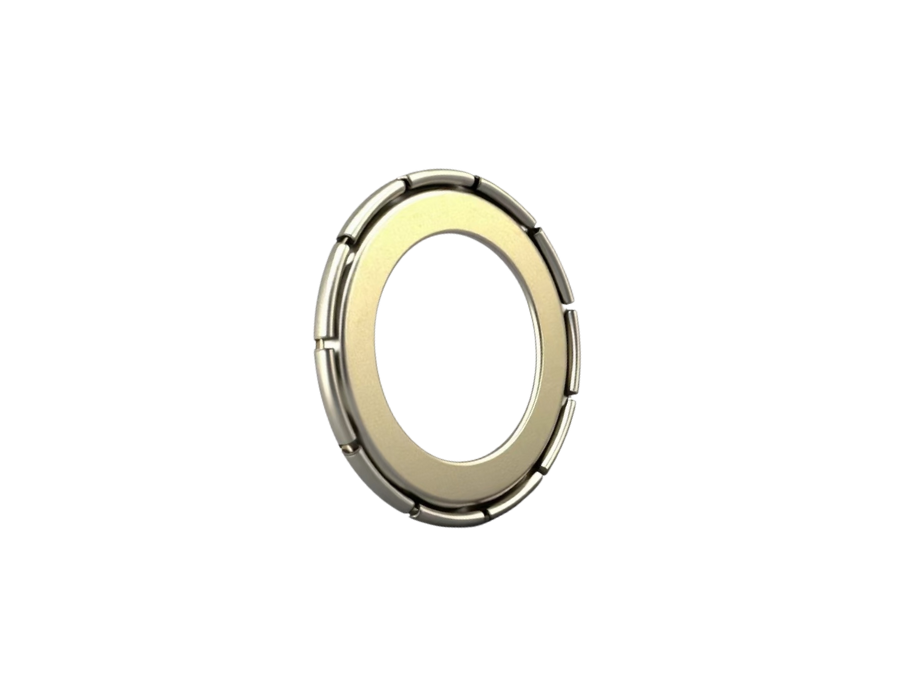

Bearing Shields

Manufacturer in China

Since 2004

Metal Bearing Shields for Precision Bearings

Bearing Shield Manufacturing

From Tooling to Mass Production

We specialize in precision bearing shield manufacturing, providing fast sampling, customized tooling, and stable mass production. With decades of stamping expertise, we ensure high accuracy, durability, and reliable performance for every shield model. Get professional support across your entire production cycle — from early development to large-scale supply.

Certification + Compliance

ISO 9001:2015 | IATF 16949:2016

The brand quality we benchmark

Our Manufacturing Services

Precision Stamping

With advanced medium-speed and high-speed presses, we produce bearing shields with consistent accuracy and efficiency. Our stamping capacity supports both large-scale production and customized small batches.

- High-volume daily output with stable quality

- Precision forming for various bearing sizes

- Flexible production to meet urgent lead times

Tooling & Mold Development

In-house tooling design and maintenance ensure that each mold delivers high precision and long service life. We support customized mold development for new bearing shield models, reducing product launch time.

- Independent mold design and fabrication

- Fast sampling and prototype validation

- Extended mold durability and reduced downtime

Surface Treatment

To ensure durability under demanding conditions, we provide a variety of surface treatments including zinc plating, nickel plating, and anti-rust oil coating. Our shields meet international corrosion resistance standards.

- Multiple protective coating options

- Salt spray test compliance for quality assurance

- Enhanced product lifespan in harsh environments

Quality Inspection & Testing

Strict quality inspection is implemented at every stage, from raw material to finished bearing shields. Equipped with advanced testing instruments, we ensure every piece meets customer requirements.

- 100% dimensional and visual inspection

- Salt spray and hardness testing available

- Complete traceability and batch reports

What’s New at YX Shield?

Four Key Dimensions for Bearing Shield Suppliers

Advanced Bearing Shield Solutions

Inspections for Bearing Shields

New Shield Selection Tool

MANUFACTURE LIKE A PRO™

We are your trusted partner for bearing shield manufacturing, from tooling design and rapid sampling to large-scale production. Partner with YX SHIELD to accelerate product development and bring your solutions to market faster. When you’re ready for mass production, our dedicated team provides complete program management—optimizing your project around cost, volume, and long-term quality assurance.

How to Work With Us

Upload Specifications

To begin, simply share your bearing shield drawings or CAD file along with required dimensions and material preferences.

Get Quote with DFM

Within hours, our engineering team will provide a manufacturability assessment and competitive pricing tailored to your needs.

Manufacturing Begins

After confirming your order, we start tooling or stamping production. Options for coatings, thickness, and special finishes are also available..

Shields are Delivered

With our streamlined production, bearing shields can be manufactured and shipped in the shortest possible lead time.

Design and Engineering Support

We are your trusted partner for bearing shield manufacturing, from tooling design and rapid sampling to large-scale production. Partner with YX SHIELD to accelerate product development and bring your solutions to market faster. When you’re ready for mass production, our dedicated team provides complete program management—optimizing your project around cost, volume, and long-term quality assurance.

Digital Manufacturing Across Your Bearing Shield Life Cycle

Full Product Life Cycle

Whether you need rapid prototype samples or stable mass production, YX SHIELD supports you across the entire bearing shield life cycle—ensuring speed, precision, and cost-efficiency at every stage.

Rapid Prototyping

Benefit from manufacturability feedback in our quotations to refine your shield design before tooling begins, then move quickly into sampling and validation.

On-Going Production

With decades of stamping experience, our team provides complete program management, optimizing your bearing shield project for cost, volume, and long-term quality assurance.

Short-Term Production

With our streamlined production, bearing shields can be manufactured and shipped in the shortest possible lead time.

Major Industries Served

YX SHIELD supplies precision bearing shields to a wide range of industries worldwide, ensuring reliability and performance in demanding applications.

Automotive

Durable bearing shields for engines, transmissions, and electric drive systems, supporting both traditional and new energy vehicles.

Industrial Machinery

High-strength shields designed for heavy-duty equipment, ensuring stable operation under high load and long service life.

Electric Motors & Appliances

Precision bearing shields for motors, fans, and household appliances, reducing friction, noise, and extending product lifespan.

Consumer & Mobility

Customized solutions for bicycles, power tools, and personal mobility devices, combining lightweight design with reliable protection.

Manufacturing Resources

Bearing Shield Manufacturing Guide

Learn how to choose the right shield type, thickness, and coating to ensure durability and performance for your bearing applications.

Bearing Shield Materials Guide

Explore the different steel grades, coatings, and surface treatments available for precision bearing shield stamping.

Cost Optimization Design Tip

Discover practical ways to reduce tooling, material, and production costs across all stages of your bearing shield development.