-

Yuyao, Ningbo City, China

Bearing Shield Quality Control

How we use digital processes, scientific molding, and inspection reporting to manufacture quality parts consistently

Certification ISO 9001:2015 | IATF 16949:2016

Our bearing shields insist on 100% inspection before leaving the factory

Design for Manufacturing (DFM) Analysis

When requesting a quotation from YX SHIELD, you will receive a detailed manufacturability analysis along with pricing.

How our manufacturing analysis improves the quality of bearing shields:

Identifies material thickness variations

Detects tolerance risks in stamping features

Reviews tooling layout and die clearance

Optimizes stamping force and press selection

Recommends finishing or coating options

Scientific Stamping: Consistently Delivering Quality Bearing Shields

At YX SHIELD, we apply a scientific stamping approach to ensure every production run is stable and repeatable. Each project follows a documented and optimized process, with full traceability of modifications. By controlling stamping pressure, forming accuracy, and surface finishing, we guarantee consistent quality—so every shield matches the previous one. This results in higher reliability, extended bearing life, and consistent inspection reports for our customers.

Design Support from Stamping Experts

Consultative Engineering Services: Work directly with our stamping engineers to improve the manufacturability of your shield design. Think of it as having your own manufacturing consultant on your team. During this process, our engineers collaborate with you to understand your application needs, review the manufacturability analysis, and refine your drawings or CAD file.

YX SHIELD Proposed Revision (YPR): In some cases, we can provide a revised CAD model—called a YX SHIELD Proposed Revision (YPR)—with improvements already made. The revised model can be used directly or serve as a reference for your design team. Once the DFM analysis and, if applicable, the YPR are approved, we move into the final preparation before mass production.

Inspections for Bearing Shields

We offer a full range of quality inspection reports for bearing shield orders. Depending on your project requirements, you can choose from the following:

CTQ Partial FAI – Focused inspection of critical-to-quality dimensions

CTQ DIR with Capability Study – Includes process capability analysis (Cp, Cpk)

Production Part Approval Process (PPAP) – Automotive-grade quality documentation

Digital Inspection Report / Full FAI – Complete dimensional inspection against drawings

Custom Inspection – Tailored reports based on customer-specific requirements

Bearing Shield Inspection Standards

As part of the YX SHIELD standard process, we measure key dimensions such as outer diameter, inner diameter, and thickness against quoted tolerances, based on your CAD model or technical drawings. These quality control checks are performed on representative samples to ensure accuracy and repeatability.

In addition, we provide a wide variety of supporting quality documentation. You can compare the benefits of each inspection report to determine which option best suits your project.

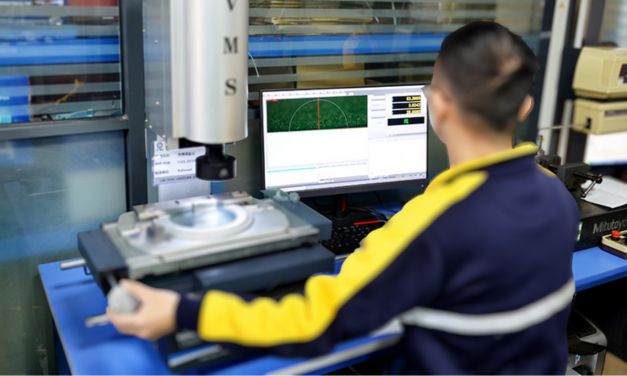

How Are Bearing Shields Measured?

We use industry-standard coordinate measuring machines (CMMs), calipers, and pin gauges, ensuring precision in every inspection. What differentiates YX SHIELD is our integration of semi-automated inspection systems, enabling in-process quality checks without extra lead time or cost.

Sampling is conducted on a cadence of n/30 (where n = total order quantity). The Capability Report includes average measurement, standard deviation, and Process Capability Index (Cpk) for all critical shield dimensions—ensuring data-driven quality assurance for every batch.

YX SHIELD – Bearing Shield Inspection Service

| Item | Description |

|---|---|

| Benefits | Provides a dimensional First Article Inspection (FAI) of critical features. Customers define the features to be inspected through an Inspection Statement of Work. |

| Measurements | Selected features may include outer diameter (OD), inner diameter (ID), thickness, concentricity, flatness, or radius identified as critical-to-quality. |

| Service Provided By | YX SHIELD Quality Assurance Team |

| Additional Features | Standardized inspection report including a bubbled part drawing and a result summary chart for easy review. |

| Eligibility | Available for all bearing shield stamping orders, including new tooling projects or repeat production orders. |

| Additional Lead Time | None for standard partial FAI. Additional time may apply if extended inspection or customer-specific standards are required. |

| Price | Default: 3-piece / up to 5-feature Partial FAI provided at no extra charge for new tooling orders. For additional parts, features, or repeat orders, FAI can be customized (starting at $500). |

| Sample Plan | After the stamping process is established, a Partial FAI is performed using samples from the first production batch. |

| Additional Information | Available under “Inspection Options” when placing an order. Customers should upload a 2D drawing with critical features marked and specify part and feature quantities required. For custom requests, please contact your YX SHIELD account representative. |

| Item | Description |

|---|---|

| Benefits | Provides a dimensional capability study (Cpk Report) of critical features to validate process stability and repeatability. Customers define the inspected features through an Inspection Statement of Work. |

| Measurements | Selected features may include outer diameter (OD), inner diameter (ID), thickness, concentricity, flatness, or radius as defined critical-to-quality dimensions. |

| Service Provided By | YX SHIELD Quality Assurance Team |

| Additional Features | Detailed inspection report including a bubbled part drawing, statistical data (mean, standard deviation), and a Process Capability Index (Cpk) summary chart. |

| Eligibility | Available for all bearing shield stamping orders. Can be added to both new projects and repeat production orders. |

| Additional Lead Time | None for standard capability studies. Additional time may be required for extended studies or customer-specific requirements. |

| Price | Default: 30-piece / up to 5-feature Capability Study provided at no additional charge for new tooling projects. For larger sample sizes, additional features, or repeat orders, capability studies can be tailored (starting at $1,000). |

| Sample Plan | Once the stamping process is established, samples are collected at evenly distributed intervals during production (minimum 30 parts) to generate a complete capability study. |

| Additional Information | Available under “Inspection Options” when placing an order. Customers should upload a 2D drawing with critical features marked and define required sample size and number of features. For tailored studies, contact your YX SHIELD account representative. |

YX SHIELD – Additional Inspection Reports

| Item | Description |

|---|---|

| Benefits | Provides comprehensive verification of critical dimensional specifications, ensuring product compliance with tight tolerances. |

| Measurements | Up to 50 measurements, including outer diameter (OD), inner diameter (ID), flatness, concentricity, hole positions, and edge angles. |

| Service Provided By | Performed by the YX SHIELD Quality Assurance Team or a certified third-party lab depending on project requirements. |

| Additional Features | Advanced 360° multi-angle 3D scanning collects precise data, identifies dimensional variance, and generates a CAD-to-scan color map for direct comparison. |

| Eligibility | Available for all bearing shield stamping projects, including prototypes and mass production runs. |

| Additional Lead Time | Typically 6+ business days, depending on complexity and sample size. Confirmed at time of order. |

| Price | Additional charges apply. Contact your YX SHIELD account representative for details. |

| Sample Plan | Random selection of samples during the stamping process, based on customer-defined sample quantity. |

| Additional Information | Can be selected under “Inspection Options” during order placement. For specific requirements, please upload a 2D drawing with defined critical features. |

| Item | Description |

|---|---|

| Benefits | Ensures systematic validation of manufacturing processes, meeting automotive and industrial quality standards. |

| Measurements | Includes dimensional verification, material certification, control plan, and process flow analysis. |

| Service Provided By | YX SHIELD Quality Assurance Team, aligned with IATF 16949 automotive quality standards. |

| Additional Features | Full documentation package for customer approval, including FAI, statistical studies, and compliance certificates. |

| Eligibility | Recommended for automotive, industrial machinery, and high-volume production orders. |

| Additional Lead Time | Determined based on project scope, typically 7–10 business days. |

| Price | Quoted per project. Contact your YX SHIELD account representative for customized support. |

| Sample Plan | Defined in collaboration with the customer, typically based on production lot sampling. |

| Additional Information | Available upon request during project kickoff. Upload customer-specific PPAP requirements to ensure compliance. |

Additional Quality Capabilities

Precision Bearing Shield Manufacturing

We specialize in precision stamping and forming of bearing shields, ensuring tight tolerances and consistent performance across high-volume production.

Custom Inspection

Additional inspection services are available, tailored to customer requirements, allowing verification of critical dimensions such as thickness, concentricity, and surface quality.

Contact your YX SHIELD representative to request a custom inspection.