-

Yuyao, Ningbo City, China

Bearing Shields for Medical Equipment

Bearings used in medical equipment must meet strict performance standards, including high speed, low noise, minimal vibration, and resistance to heat, wear, and chemical exposure.

Bearing Shields for Medical Equipment Manufacturer in China

In this environment, bearing shields play a critical role by:

Preventing contamination from fluids, dust, or sterilization agents

Protecting the lubricant inside the bearing during high-speed operation

Reducing noise and vibration by maintaining internal cleanliness

Improving durability when exposed to corrosive cleaning chemicals or bodily fluids

|

Advantages

|

Remark

|

|---|---|

|

High sealing

|

Prevent liquids, medicines, and cleaning agents from penetrating into the bearings

|

|

Quiet performance

|

Maintain lubrication integrity, reduce friction and vibration

|

|

Corrosion resistance

|

Especially stainless steel, resistant to corrosion by chemicals, hydrogen peroxide, alcohol and other disinfectants

|

|

Easy to clean

|

The metal cover is smooth and has no dead corners, suitable for hospital-level cleaning processes

|

|

Extend bearing life

|

Reduce lubrication loss, avoid frequent replacement and maintenance

|

Stainless steel shields (SUS304 or SUS316) are commonly used for their non-corrosive and hygienic properties, making them ideal for applications such as centrifuges, surgical instruments, imaging equipment, and robotic arms.

Applications of Bearing Shields in the Medical Industry

Typical applications include:

Ventricular assist devices (VADs)

Medical diagnostic equipment

Surgical robots and powered surgical tools

Radiation therapy machines

Blood analyzers and infusion systems

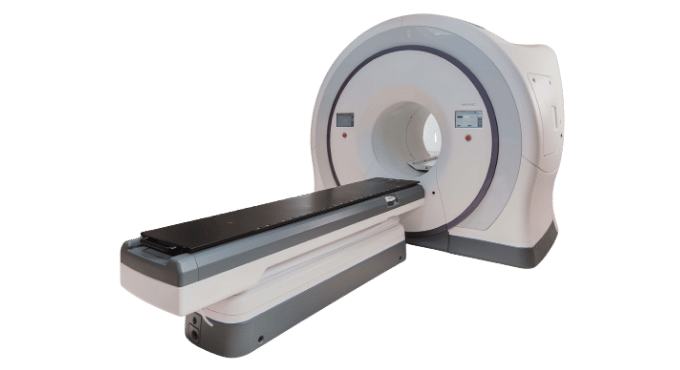

CT scanners and imaging equipment

Prosthetics and exoskeletons

Pharmaceutical dispensers

Dental turbines and handpieces

Laboratory analyzers and automation systems

Advantages of Bearing Shields in Medical Bearings

When combined with high-precision metal shields (Z or ZZ types), our bearings deliver:

Enhanced cleanliness and contamination control

Stable operation under continuous or high-speed use

Improved protection against sterilization chemicals and fluids

This level of precision and shielding performance ensures that our bearing solutions operate reliably and safely across a wide range of medical devices, from surgical tools to diagnostic equipment.

Stainless Steel Bearings with Shields: Ideal for Medical Use

Stainless steel bearings offer superior resistance to rust and corrosion compared to standard steel, making them ideal for repeated cleaning and sterilization in medical environments. They are also a more cost-effective alternative to ceramic bearings, which is why they are commonly used in a variety of medical devices.

For added protection, especially in environments exposed to moisture, disinfectants, or biological fluids, these bearings are often paired with metal bearing shields (such as ZZ-type). The shields help:

Prevent contamination from external particles or liquids

Retain lubrication during high-speed or continuous use

Extend bearing lifespan with minimal maintenance

This combination ensures hygienic, reliable, and efficient bearing performance in critical medical applications.

| Material | Key Benefits |

|---|---|

| SUS304 Stainless Steel | Rust-resistant, ideal for standard sterilization |

| SUS316 Stainless Steel | Superior chemical resistance, ideal for autoclaves and disinfectants |

| Nickel-plated Steel | Improved aesthetics and corrosion resistance for low-contact zones |

Bearing shields help prevent contaminants—such as fluids, cleaning chemicals, dust, and biological particles—from entering the bearing. This ensures smoother operation, extends service life, and improves safety and reliability in sensitive medical environments.

Yes. Stainless steel shields (especially SUS316) are highly resistant to high-temperature steam sterilization (autoclaving), hydrogen peroxide, and alcohol-based cleaning agents. They maintain structural integrity and sealing performance after repeated sterilization cycles.

Bearing shields are commonly found in:

Surgical robots and powered hand tools

CT and MRI scanners

Dental turbines and ultrasonic equipment

Infusion systems and blood analyzers

Prosthetics and exoskeleton joints

Absolutely. By sealing out contaminants and retaining lubrication, bearing shields help minimize the need for frequent cleaning, re-lubrication, or replacement—especially in equipment that runs continuously or in sterile fields.

Yes. We offer custom shield designs in terms of:

Material (SUS304 / SUS316 / plated steel)

Thickness and lip geometry

Press-fit tolerance and coating finish

This ensures compatibility with your device requirements and environmental standards.