-

Yuyao, Ningbo City, China

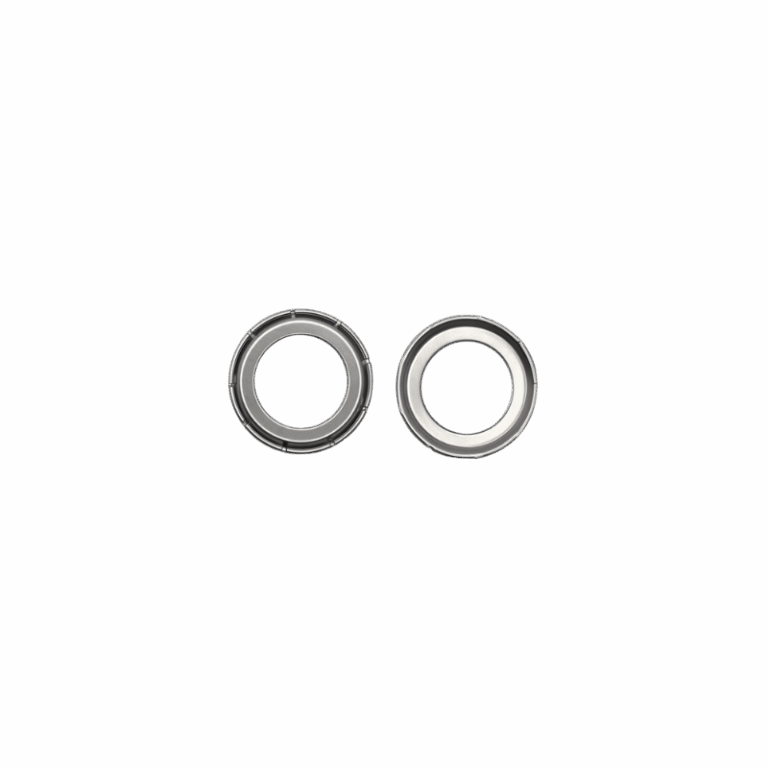

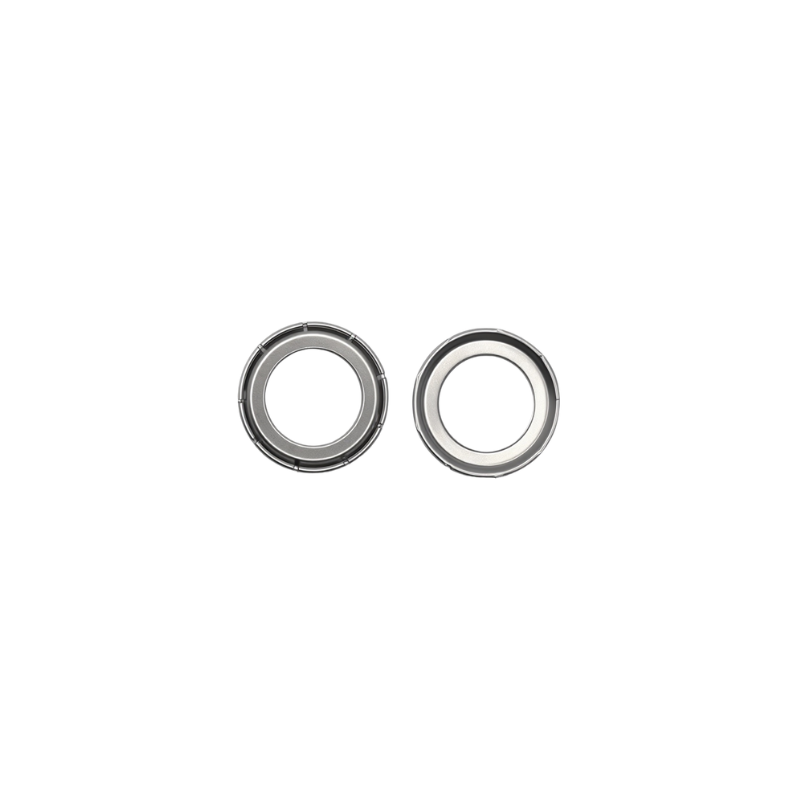

608Z/ZZ Bearing Shield

Details of 608 Metal Shield

Precise Fit, Protective Foundation

Tailor-made for 608 bearings, achieving a millimeter-level fit with the bearing edges. After installation, it forms a sealed protective space, like adding “protective armor” to the bearing, blocking the intrusion path of dust, sand, oil stains and other foreign matters from the source, and avoiding bearing jamming, abnormal noise and other problems caused by impurity wear.

Military-grade Metal Material, Hardcore Durable

Made of 304 stainless steel / high-carbon steel, after high-temperature quenching process, the surface hardness reaches 50-55HRC, and the impact strength exceeds 120MPa. The metal body can withstand extreme temperature differences from -40℃ to 200℃. In humid workshops, outdoor equipment and other scenarios, it passes 240-hour salt spray test without rust, and its service life is more than 3 times longer than that of ordinary plastic shields.

Three Performance Advantages, Exceeding Industry Standards

- All-condition Dustproof: The edge adopts a crimping and interlocking design, combined with stamping process with 0.02mm precision, the dustproof grade reaches IP65. When continuously operating for 5000 hours in an environment with dust concentration of 10mg/m³, the internal cleanliness of the bearing remains above 98%.

- Dynamic Stability: The rigid support of the metal material can offset the radial force generated by the high-speed rotation of the bearing. At 3000r/min, the radial runout is controlled within 0.01mm, ensuring stable operation of the equipment.

- Maintenance-free Feature: The surface is electrolytically polished, with a friction coefficient as low as 0.08, which can be used for a long time without additional lubrication, reducing the number of equipment shutdowns for maintenance.

Multi-scene Adaptation List

- Industrial equipment: servo motors, gearboxes, conveyor bearing sets

- Sports equipment: electric skateboards, fitness equipment rollers, roller skate bearings

- Home appliance field: vacuum cleaner motors, air conditioner fan bearings, washing machine drum bearings

- Outdoor equipment: lawn mowers, power tools, UAV landing gear bearings

Model Segmentation and Selection Suggestions

| Model Suffix | Structural Features | Application Scenarios |

|---|---|---|

| 608ZZ | Double-sided metal shield | Dry and dusty environments, medium and high-speed operating equipment |

| 608Z | Single-sided metal shield | Bearing components requiring heat dissipation on one side |

(Note: The ZZ model adopts a symmetrical double-shield design, which has better dustproof effect than the single-shield model. It is recommended to choose it for precision instruments and equipment first)

Quality Traceability and After-sales Guarantee

Each batch of products is accompanied by material testing reports, including 12 indicators such as hardness, composition, and rust resistance. If the bearing is damaged due to the product’s own quality problems, free replacement will be provided with the test report and maintenance costs will be borne.

(Attached: Product real shot pictures / material testing report samples / installation diagram links)

Special note: The weight of the metal shield is only 1.2g, which has negligible impact on the overall weight of the equipment. There is no need to adjust the bearing preload parameters during installation.

Help Center

Have a query? Please check this question and answers

We offer a wide range including loose type shields, crimped edge shields, right-angle edge shields, and fully customized bearing shields based on client drawings or samples.

Yes. We specialize in custom stamping solutions and can develop tooling based on your drawings, specifications, or samples. OEM and ODM are both welcome.

Our shields are typically made from galvanized steel, stainless steel (201/304), or cold-rolled steel. We can also recommend materials based on your application needs.

Yes. We offer samples for evaluation, and custom samples can also be produced within a short lead time.

Tooling development usually takes 15–30 days, depending on the complexity of the design. Sample delivery follows immediately after.

Yes. We are IATF16949,ISO 9001 certified and can provide RoHS, SGS, material test reports, and other compliance documentation upon request.

We currently export to Europe, North America, Southeast Asia, and the Middle East, with long-term clients in Germany, Brazil, the U.S., and more.

Lead time is usually 7–15 days after order confirmation, depending on quantity and whether new tooling is required.