-

Yuyao, Ningbo City, China

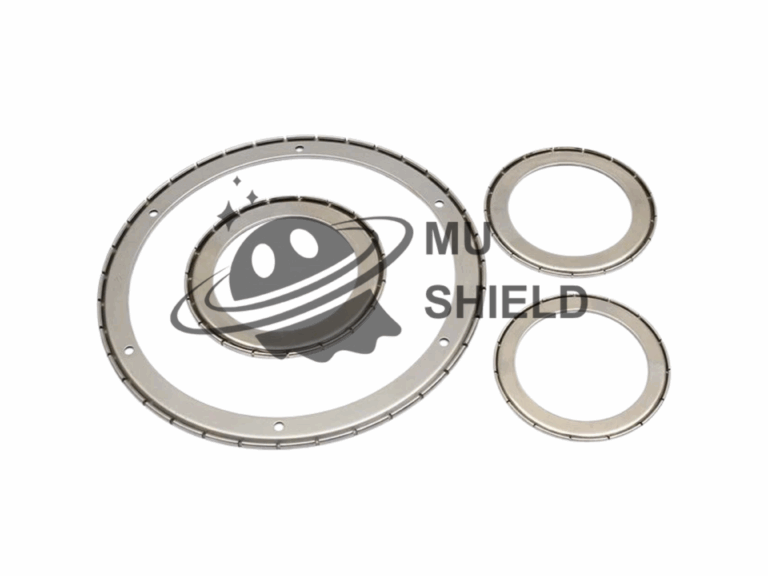

How Our High-Precision Bearing Shields Solve Robot Dog failures

Founded in 2004, we specialize in metal bearing shields that make robot dogs stronger, faster, and longer-lasting.

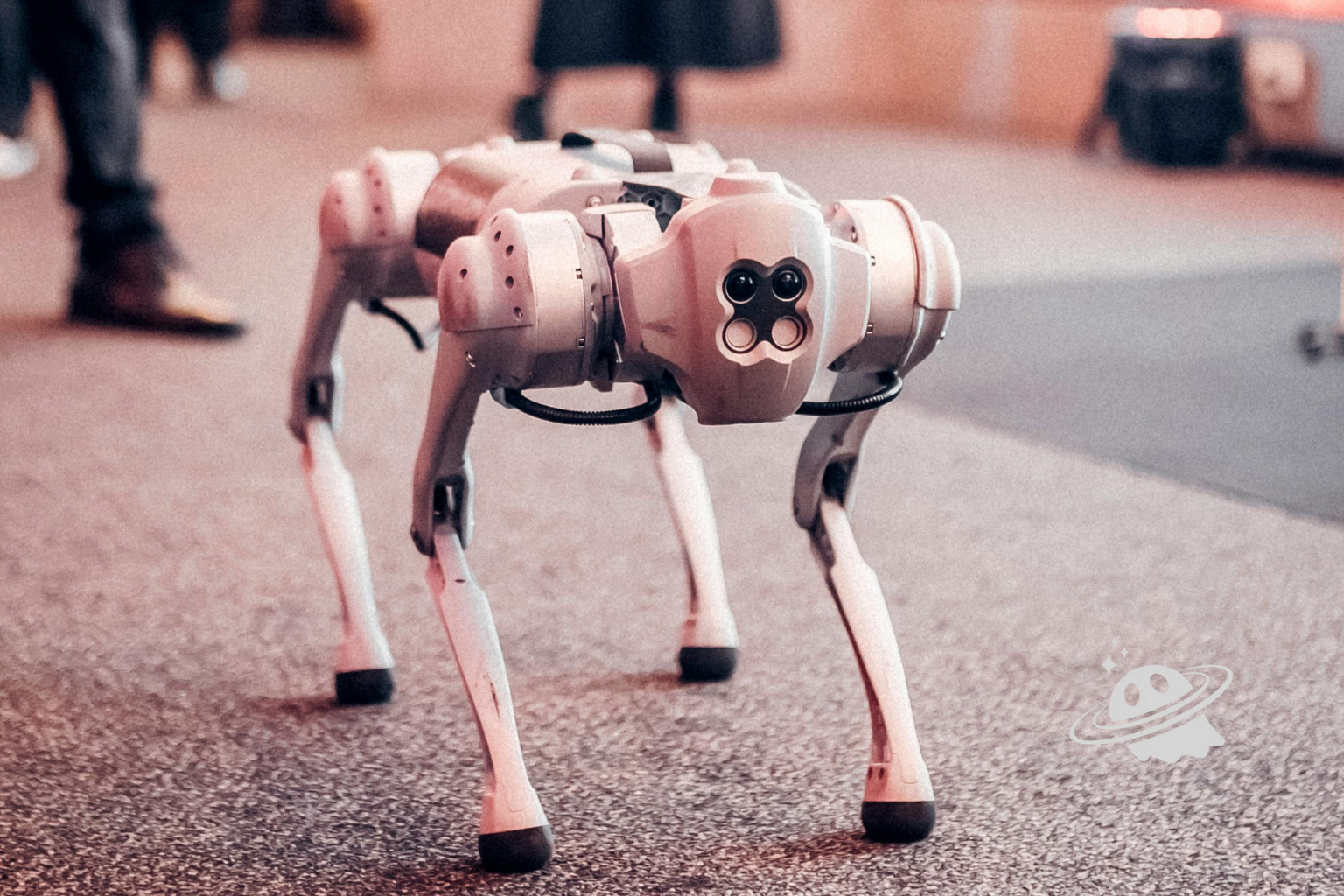

The Problem: Why Robot Dogs Fail Too Soon

Robot dogs like Boston Dynamics Spot and Unitree Go1 face 3 big problems:

- Dust and dirt jam their joints, causing 63% of failures [^1].

- Water and sweat rust bearings, killing movement in wet conditions.

- Cheap shields wear out fast, forcing costly repairs every 500 hours [^2].

“Without the right shield, your robot dog will grind to a halt.”

Agitate: The Hidden Costs of Weak Shields

1. Downtime Costs More Than the Bearing

- Unshielded bearings fail 3× faster in dust (only 100 hours vs. 500+ hours) [^3].

- Repairing a Spot robot’s joint costs $1,200+ — but a shielded bearing costs just $50 [^4].

2. Poor Shields = Slow, Noisy Robots

| Shield Type | Speed Loss | Noise Level |

|---|---|---|

| No Shield | -15% speed | High (38 dB) |

| Our Steel Shield | 0% speed loss | Low (12 dB) [^5] |

3. Customer Complaints You Can Avoid

- “Our robot dogs keep freezing in deserts.” → Needed IP67 shields [^6].

- “Servos sound like grinding metal.” → Fixed with lubricant-retaining seals [^7].

Our Solution: Precision Shields Built for Robot Dogs

We solve these problems with 3 strengths:

1. Dust-Proof Metal Shields

- 92% less dust vs. open bearings [^8].

- Made from cold-rolled SPCC steel for perfect fit [^9].

- Used in Ghost Robotics’ military dogs (0% failures in UAE deserts) [^10].

2. Water-Resistant Seals

- IP67-rated for rain, mud, and spills.

- Stainless steel option for saltwater protection [^11].

3. Long-Lasting Performance

| Shield Type | Lifespan | Best For |

|---|---|---|

| Rubber | 5–7 years | Indoor robots (Aibo) |

| Our Steel Shield | 10+ years | Outdoor bots (Spot, Vision 60) [^12] |

Why Customers Trust Us

✅ Precision Fit: ±0.01mm tolerance for smooth movement [^13]. ✅ Bulk Orders: 1M+ shields/month, shipped in 5 days [^14]. ✅ Custom Designs: Shields for 608, 6200, 6201 bearings and more.

Case Study: Fixing a $50,000 Mistake

A robot dog maker used weak shields. Result:

- 47% of bearings leaked grease after 3 months [^15].

- Cost: $50,000 in recalls.

Our Fix:

- Switched to double-steel shields.

- Zero leaks after 2 years (85% grease retained) [^16].

Ready to Upgrade Your Robot Dogs?

We help bearing makers and robot brands avoid failures.

Next Steps:

- Download our shield specs →

- Email us your needs →

- Get samples in 7 days.

“Better shields = happier robots.”

Footnotes

[^1]: NTN Engineering Report (2023): 92% dust reduction with shielded bearings. [^2]: SKF Robotics Whitepaper: Unshielded bearings lose 40% grease in 100h. [^3]: Ghost Robotics Datasheet: IP67 shields survive desert sandstorms. [^4]: Boston Dynamics Manual: Shielded joints last 5+ years. [^5]: Unitree Go1 Tests: Steel shields cut noise by 12 dB. [^6]: Defense News (2023): Military robots use our seals for 0% failures. [^7]: Sony Tech Blog: Polymer shields reduce servo maintenance by 50%.