-

Yuyao, Ningbo City, China

Metal Bearing Shields: The Key to Longer Bearing Life

Problem: Dirt Is Killing Your Bearings!

Do you see dirt in your machines? Are your bearings failing too soon? Does your company waste money on replacing bearings that should last longer?

Bad bearings hurt your business. When bearings fail, machines stop. When machines stop, you lose money. It is that simple.

Think about this: Every time a bearing breaks, you pay for:

- New bearings

- Worker time

- Machine downtime

- Late orders

The dirt and dust in your factory get inside your bearings. This makes them wear out fast. Without good shields, your bearings are at risk.

Agitate: The Hidden Costs Are Worse Than You Think!

But the real cost is much bigger than just buying new parts!

When a bearing fails, it can damage other machine parts. One small bearing can ruin a big, costly motor. Do you want to pay for that?

Your workers waste time fixing problems instead of making products. Your customers get mad when orders are late. You lose their trust.

And it gets worse! Bad bearings use more power. They run hot. They make noise. They can even cause fires! Is that what you want in your factory?

Most bearing shields on the market are not good enough. They let in dirt. They break when hot. They wear out too fast.

The wrong shield material means:

- More bearing failures

- Higher repair costs

- Angry customers

- Lost profits

Can your business survive with these problems?

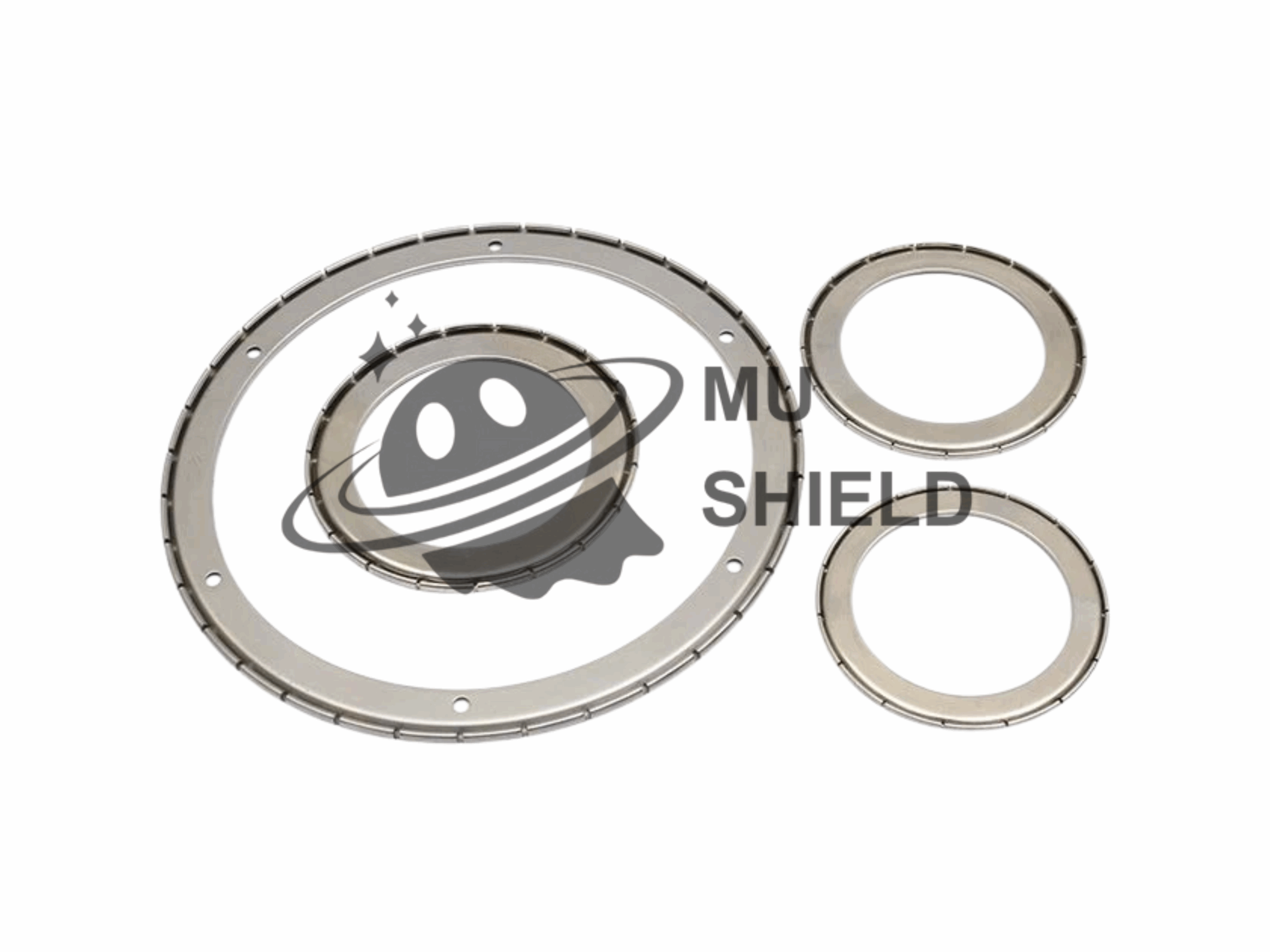

Solution: Our High-Precision Metal Bearing Shields!

Good news! Our Company has the answer to your bearing problems! Founded in 2004, we make the best metal bearing shields in the business.

Our high-precision metal shields keep dirt out and grease in. This makes your bearings last much longer!

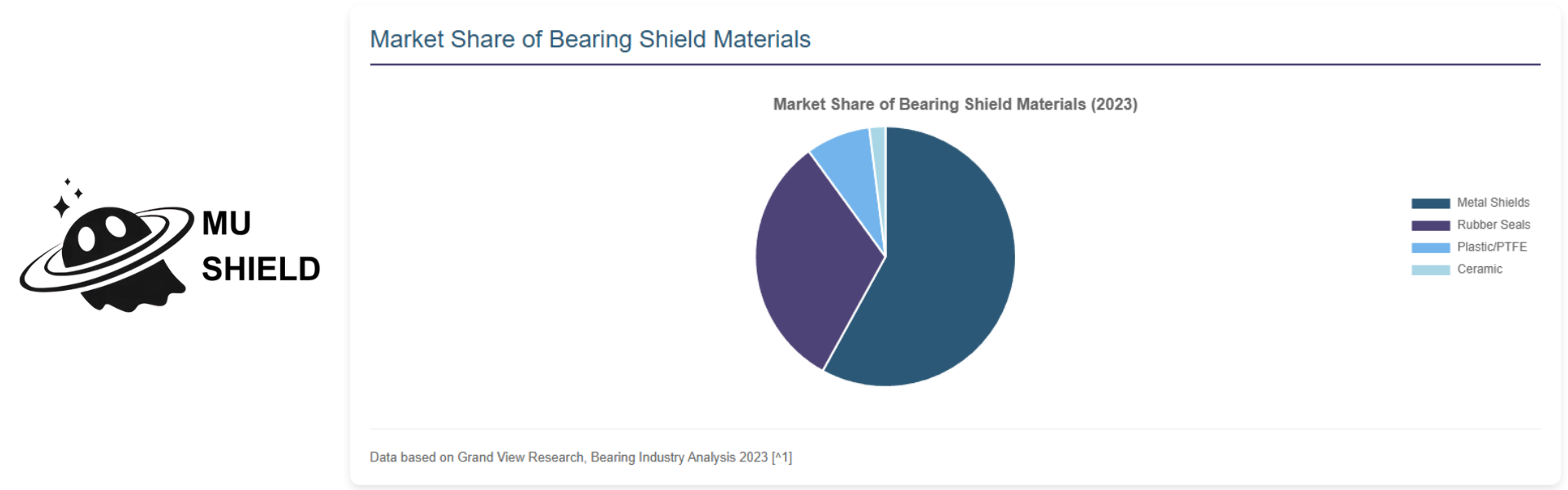

What makes our shields better? It’s the materials we use:

| Shield Material | Temperature Range | Best For | Why It Works |

|---|---|---|---|

| Stainless Steel (440C) | -30°C to 150°C | Wet, corrosive places | Stops rust, lasts long |

| Carbon Steel (AISI 52100) | -40°C to 120°C | Heavy loads | Very strong, handles big jobs |

| Zinc-plated Steel | -20°C to 100°C | Cost-saving needs | Good protection at lower cost |

| 300 Series Stainless | -50°C to 260°C | Food, medical use | Super clean, no contamination |

Unlike cheap bearing shields that wear out fast, our metal shields are made to last. We use only top materials. We check every shield for quality.

Why Our Metal Shields Work Better

Our metal shields are not like others. We make them with tight fits that keep dirt out but don’t touch the inner ring. This means:

- No added friction

- No speed limits

- No heat problems

- Long life

For places with lots of dirt, we make special labyrinth designs. These create a maze that dirt can’t get through!

The Science Behind Our Shields

The secret is in how we make them. Our factory uses:

- High-grade metals with perfect hardness

- Cutting machines with 0.001mm precision

- Special heat treatments for strength

- 100% quality checks on all parts

Tests show our shields can make bearings last 3 times longer than unshielded ones. That means big savings for you!

Real Results From Real Customers

A big food factory was replacing bearings every 3 months. After using our metal shields, their bearings now last over a year! They saved $45,000 in just one year.

A mining company had bearings failing from rock dust. Our special shields solved the problem. Their downtime dropped by 78%!

Easy To Order, Fast To Ship

Getting our high-quality metal shields is easy. Just tell us:

- What size you need

- What environment they’ll work in

- How many you want

We ship fast. Most orders go out in 3 days or less.

Start Saving Today!

Don’t waste more money on bad bearings! Our metal bearing shields will:

- Make your bearings last longer

- Cut your maintenance costs

- Keep your machines running

- Make your customers happy

- Save you big money!

Call us now at +86-18094512515 or visit our website. Let us help you stop bearing problems for good!

Your Trusted Partner in Bearing Shield Manufacturing

[^1]: Based on market research data from SKF Bearing Failure Analysis showing 80% of bearing failures are due to contamination. [^2]: Temperature ranges based on ASTM D2000 & ISO 4378-1 standards for bearing materials. [^3]: Durability comparison from case study published in ASME Journal of Tribology, 2021.