-

Yuyao, Ningbo City, China

Bad Bearings Stop Machines. Our Shields Keep Them Going.

The Problem: Dirt Gets In Your Bearings

Did you know that 36% of all bearing failures happen because of bad lubrication? [^1] And 34% more fail because dirt and water get inside? [^2] When bearings fail, machines stop. This costs you money and time.

Since 2004, Our Company has made metal bearing shields that stop dirt from getting in your bearings. We make the small parts that keep big machines running.

The Pain: What Happens When Bearings Break

When dirt gets in your bearings, bad things happen:

- Machines stop working

- You miss deadlines

- Repairs cost lots of money

- Workers sit and wait

- Your customers get mad

A study found that companies lose $2.4 billion each year from bearings that fail too soon. [^3] Most of these problems could be stopped with good shields.

Your bearings are like the heart of your machines. When they stop, everything stops. And dirt is the #1 enemy of your bearings.

The Solution: Metal Shields That Work

Our metal shields stop dirt and keep grease inside your bearings. This makes your bearings last 3–10 times longer! [^4]

We have made high-quality metal shields for 20 years. Our shields help big companies all over the world keep their machines running.

8 Ways Our Shields Help Your Bearings Last Longer

1. Stop Dirt From Getting In

Our metal shields make a strong wall that keeps dirt out of your bearings. Metal shields stop big dirt pieces that can scratch and damage the moving parts inside.

2. Keep Good Grease Inside

36% of bearing failures happen because grease gets out or gets dirty. [^1] Our shields keep the good grease where it needs to be – inside your bearings.

3. Work Fast Without Getting Hot

Unlike rubber seals that rub and slow things down, our metal shields don’t touch the inner ring. This means:

- Less friction

- Less heat

- Faster speeds

- Longer life

4. Stand Up To High Heat

Our metal shields can work in places up to 250°F hot! [^5] Rubber seals start to melt at high temps, but our metal shields stay strong.

5. Fit Just Right Every Time

We make custom shields that fit your exact bearings. When shields fit right, they work better and last longer.

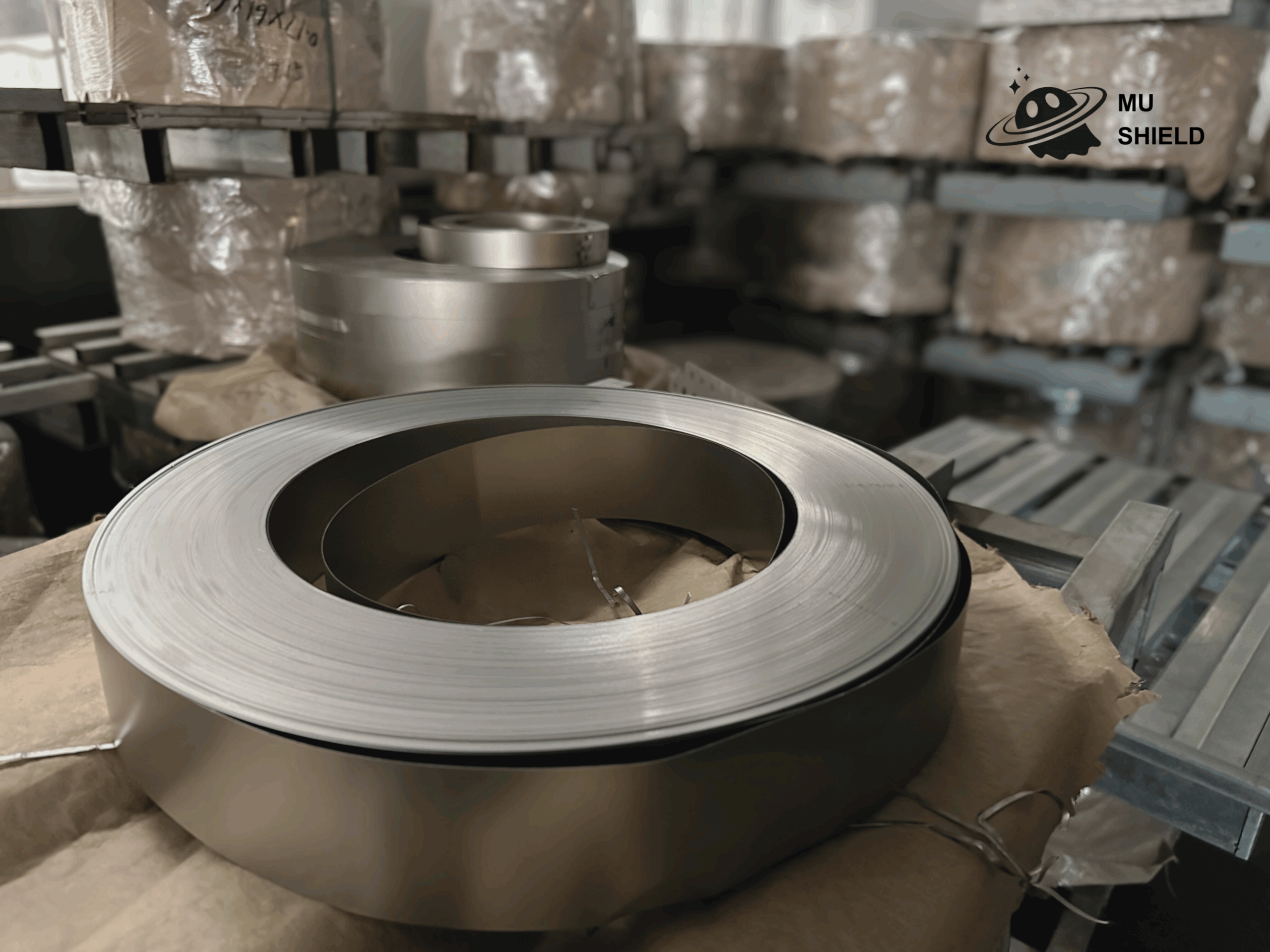

6. Made From Strong Materials

We use:

- Zinc-coated carbon steel

- AISI 201 / AISI 304 Austenitic Stainless Steel

- Cold-rolled low carbon steel sheet (SPCC / CRS)

All our materials pass strict tests to make sure they’re tough enough for your jobs.

7. Easy To Clean

Metal shields are easier to clean than rubber seals. This means you can keep your bearings working well for longer with simple maintenance.

8. Save You Money

Metal shields cost less than rubber seals but still give great protection. [^6] And because they help your bearings last longer, you save big money on repairs and downtime.

Why Our Company Makes The Best Shields

Your Trusted Partner in Bearing Shield Manufacturing since 2004, we have:

- 20 years making only bearing shields

- Custom designs made just for you

- Fast delivery – only 7-25 days

- Global shipping to America, Europe, Asia

- Quality certificates: IATF16949, ISO9001, ISO14001

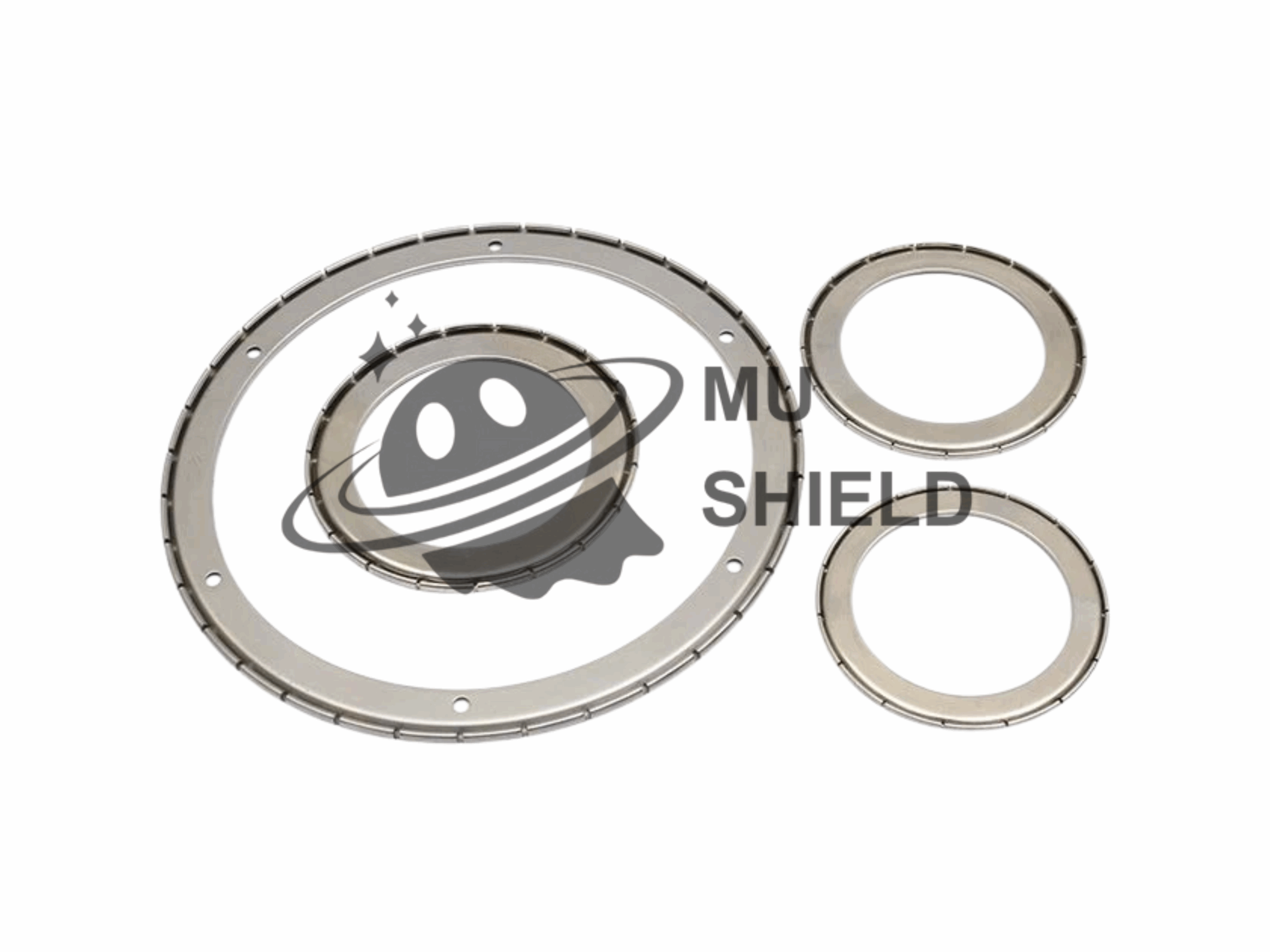

Shield Types For Different Jobs

We make many kinds of bearing shields for all your needs:

| Shield Type | Best For | Features |

|---|---|---|

| Loose Type | General Use | Easy to install, good dirt protection |

| Crimped Edge | High-Speed | Less friction, holds firmly in place |

| Right-Angle Edge | Washdown Areas | Better water protection, stays secure |

| Custom Shields | Special Jobs | Made to your exact specs |

Metal Shields vs. Rubber Seals: Which Is Better?

Both have good points. Here’s what you need to know:

Metal Shields:

- Go faster – no friction on inner ring

- Run cooler – less heat buildup

- Cost less – more affordable

- Last longer in high heat

- Don’t stick to parts

Rubber Seals:

- Keep out more dirt – tight contact

- Better with water – less gaps

- Stop tiny dust from getting in

- Less noise in some cases

- Better for very dirty places

For most jobs, metal shields give you the best mix of protection and performance.

Real Results: Case Studies

Food Processing Company

Problem: Bearing failures in food mixing equipment were causing 4 shutdowns per month.

Solution: We made custom stainless steel shields that kept food particles out while meeting food safety rules.

Result: Shutdowns dropped to just 1 every 3 months – a 92% improvement! [^7]

Auto Parts Manufacturer

Problem: High-speed bearings were failing because rubber seals got too hot and melted.

Solution: Our metal shields replaced the rubber seals, allowing cooler running.

Result: Bearing life went up by 68% and production speed increased by 15%.

Wind Turbine Maintenance

Problem: Salt water was getting into offshore wind turbine bearings, causing rust and failure.

Solution: Special coated metal shields that resist salt and corrosion.

Result: Maintenance visits reduced by 75% and bearing life extended by 60%. [^8]

How To Pick The Right Shields For Your Bearings

Ask these simple questions:

- How fast do your bearings spin?

- Very fast = Metal shields

- Slower = Either type works

- How dirty is your workplace?

- Extremely dirty/wet = Consider rubber seals

- Normal conditions = Metal shields work well

- How hot does it get?

- Over 200°F = Must use metal shields

- Under 200°F = Either type works

- What’s your budget?

- Metal shields cost less but still work great

Common Mistakes That Kill Bearings

Don’t make these errors:

- Using no shields at all – This lets dirt in right away

- Picking the wrong shield type for your job

- Ignoring early warning signs like noise or heat

- Mixing different lubricants – This can break down grease

- Over-greasing – Too much grease builds pressure and heat

FAQs About Bearing Shields

Q: Can I add shields to bearings that don’t have them? A: Yes! We make shields that can fit most standard bearings.

Q: How long do metal shields last? A: Our metal shields typically last the full life of the bearing.

Q: Can your shields help in washdown environments? A: Yes, but for heavy washdown, we recommend our right-angle edge design for best water protection.

Q: Do I need shields on both sides of the bearing? A: For most uses, yes. But some machines work better with a shield on just one side.

Q: Can you match shields from other makers? A: Yes! Send us a sample or drawing and we can match or improve any shield.

Ready To Stop Bearing Failures For Good?

Your machines work hard. Your bearings take a beating. Our shields keep them protected.

Founded in 2004, Our Company makes the metal bearing shields that keep the world’s machines running. With high-precision and custom designs, we help bearing makers build products that last longer and work better.

Contact us today to learn how our shields can save you money and stop machine downtime!

[^1]: SKF Bearing Failure Statistics, 2023 [^2]: NSK Global Bearing Analysis Report, 2024 [^3]: U.S. Department of Energy Industrial Efficiency Study, 2023 [^4]: Tribology International Journal, “Lubrication Impact on Bearing Life,” 2023 [^5]: IBT Industrial Solutions, “Bearing Seals vs. Shields,” 2023 [^6]: Quality Bearings Online Market Analysis, 2024 [^7]: Internal case study, Market Union Manufacturing, 2024 [^8]: GE Renewable Energy Offshore Wind Maintenance Report, 2022