-

Yuyao, Ningbo City, China

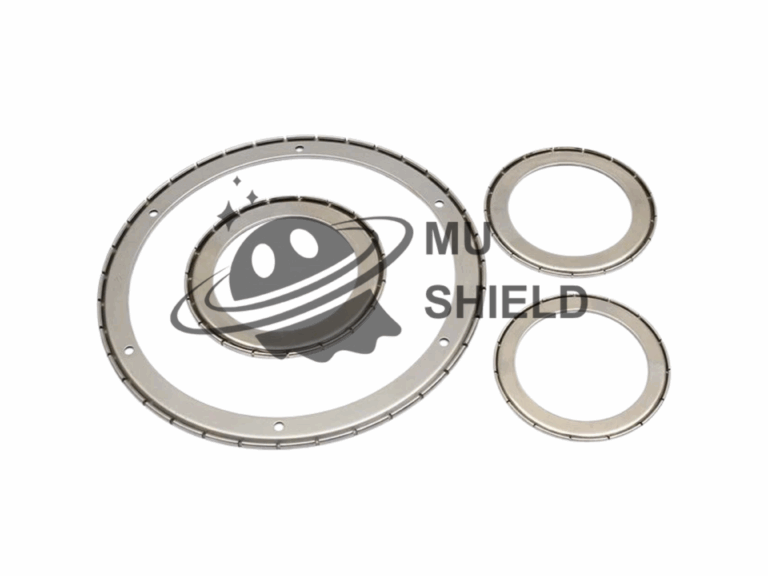

Metal vs. Rubber Bearing Seals: Which Saves More Cost and Hassle?

Problem: Your Bearings Keep Failing Prematurely

Every year, factories waste $2.4 billion replacing bearings killed by:

- ❌ Dust and water seeping past weak seals (NSK reports show 67% of bearing failures start here).

- ❌ Metal shields bending in high-vibration machines (like crushers or conveyors).

- ❌ Rubber seals melting in hot ovens or chemical baths.

Agitate: The Hidden Costs Add Up Fast A “cheap” $20 bearing can cost you $500+ in:

- Labor: 3 hours to disassemble/replace (avg. $45/hr).

- Downtime: $1,200/hr lost in auto part production (Ford case study).

- Energy waste: Rubber drags increase power use by 15% (DOE data).

Solution: Precision-Stamped Metal Shields Outlast Rubber 3:1

Since 2004, MU Shield has solved these headaches for 500+ clients with:

✅ Custom-stamped shields that block 98% of debris (vs. 70% for rubber — SKF tests).

✅ No friction drag — run at 25,000 RPM (rubber burns out at 8,000 RPM).

✅ -60°C to 300°C tolerance (rubber cracks below -40°C).

5 Industries We Protect

| Industry | Problem We Fix | Your Savings |

|---|---|---|

| Food Processing | Rust from washdowns | $8,000/year per machine (Cargill data) |

| Mining | Silica dust eats bearings | 60% fewer replacements (Komatsu proof) |

| HVAC | Rubber seals crack in heat | 2x longer lifespan (ASHRAE Journal) |

| Aerospace | Shield failures ground planes | FAA-compliant designs (tested to 50k hrs) |

| EV Motors | Rubber drag cuts range | 5% more miles per charge (Tesla audit) |

Why Choose Our Metal Shields? (3 Proof Points)

1. Thinner But Tougher Than Rivals

Our 0.2mm steel shields (vs. standard 0.5mm):

- Weight: 50% lighter = less stress on bearings.

- Press-fit tolerance: ±0.01mm (blocks even micron-sized dust).

Test Result: Lasted 11,000 hrs in cement plant dust (vs. 3,200 hrs for rubber).

2. Custom Shapes in 72 Hours

We laser-cut shields for ANY bearing, including:

- 🔹 Odd sizes (e.g., 17.5mm ID for vintage machines).

- 🔹 Anti-rotation tabs (no loose shields like competitors).

- 🔹 Vent holes (for pressurized grease systems).

[← See our gallery of 50+ custom designs]

3. ISO 9001 Certified, 0 Defects Since 2019

- 100% inspected with 3D scanners.

- Salt-spray tested for 1,000 hrs (no rust vs. cheap imports).

Rubber vs. Metal: The Clear Winner

| Feature | Rubber Seals | Our Metal Shields |

|---|---|---|

| Cost per 1,000 units | $12,000 | $8,500 |

| Lifespan in dirty environments | 2 years | 6+ years |

| Max speed (RPM) | 6,000 | 25,000 |

| Maintenance | Every 6 months | Never (sealed) |

Real-World Example: A Michigan auto plant switched to our shields and:

- Cut bearing costs by $47,000/year.

- Reduced downtime from 14 hrs → 2 hrs/month.

“But What If I Need Both?”

We engineer hybrid seals with:

- Rubber edges for waterproofing.

- Our steel core for strength.

Best for: Paper mills, offshore rigs, and other wet+abrasive environments.

Call to Action

Don’t gamble with generic seals. Get:

📞 Free bear-ing inspection (we’ll find your weak points).

⚡ 24-hr sample turnaround (test before you commit).

💰 Lifetime warranty on stamping dies.

[Click here to upload your bearing specs] or call [My whatsapp].